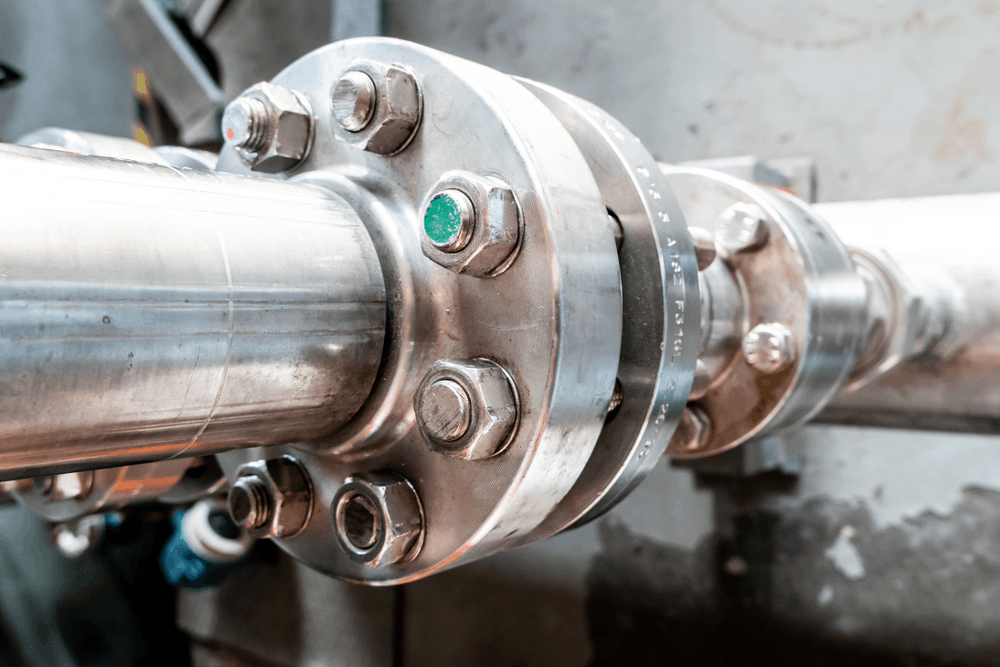

A flange is a mechanical device used to connect pipes, valves, pumps, and other equipment in a piping system. It allows for easy assembly, disassembly, inspection, and maintenance. Flanges are essential for creating secure, leak-proof connections.

What Is a Flange?

Flange Standards

Every flange is manufactured to a flange standard. The standard defines the outside diameter, thickness, hole size and the PCD the holes are drilled on, as well as many other characteristics of the flange.

AS2129 (Table D, Table E, Table F, Table H, Table J) AS4087 (PN16, PN21, PN35) Applications: For water industry and other general uses.

Types of Flanges

Every flange is manufactured to a flange standard. The standard defines the outside diameter, thickness, hole size and the PCD the holes are drilled on, as well as many other characteristics of the flange. You need to know the standard you flange is made to. This site has a tool (link) to identify your flange size and standard. Additionally dimension tables for common standards are available. The most common Flange standards and a brief overview are as follows:

Tapered hub, butt-welded connection.

High-pressure, high-temperature services.

Slip over pipe, welded inside and outside.

Low to medium-pressure systems.

No bore, seals end of piping systems.

Testing, isolating sections for maintenance.

Internal threads, no welding needed.

Interface between non-threaded and bolted systems

Pipe inserted into socket, fillet welded.

Small-size, high-pressure pipelines.

Flange Materials

Each flange standard will have a list of approved materials that can be used to make the specific flange.

Properties: Excellent corrosion resistance, high temperature tolerance.

Grades: 304/304L, 316/316L, Duplex.

Applications: Chemical, food, marine, pharmaceutical industries.

Flange Measurement

Technical Resources

Access valuable resources to support your project.

Flange Applications

Our flanges are used across various industries.

Pipelines, refineries, drilling rigs.

Chemical plants, storage facilities.

Thermal, nuclear plants.

Desalination, wastewater systems.

Processing equipment, hygienic piping.

Clean rooms, sterile processing systems.

Why Choose Balcombe Engineering

Flanges meeting international standards (ANSI, DIN, JIS, AS).

Wide selection of flange types, sizes, and materials.

Real people, knowledgeable and experienced. Ready to assist with your needs

High-quality flanges at affordable prices.

Prompt service across Australia.

Able to manufacture flanges to your custom drawing specifications.