Understanding Pipe Elbows: Types and Applications

A pipe elbow is a fitting installed between two lengths of pipe or tubing to allow a change of direction, usually at a 90° or 45° angle. Elbows are essential components in piping systems, facilitating fluid flow in various directions. Key features include:

- Common Angles: 90°, 45°, and 180° (return elbows)

- Radius Types:

- Long Radius (LR) Elbows

- Short Radius (SR) Elbows

- Materials Available:

- Carbon Steel

- Stainless Steel

- Alloy Steels

- Applications:

- Oil and Gas Industry

- Chemical Processing

- Water Treatment Systems

Industrial Nozzles: Functions and Importance

A nozzle is a device designed to control the direction or characteristics of a fluid flow as it exits or enters an enclosed chamber or pipe. In industrial applications, nozzles are crucial for:

- Directing Flow

- Controlling Velocity/Pressure

- Optimizing Efficiency

They are used in various settings, including:

- Pressure Vessels

- Boilers

- Piping Systems

Pipe Spools: Fabrication and Applications

A pipe spool is a prefabricated component of a piping system, consisting of pipes, fittings, and flanges that are welded or assembled in the fabrication shop before installation on-site.

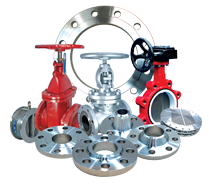

Long Weld Neck Flanges: Features and Uses

Long Weld Neck (LWN) flanges are similar to standard weld neck flanges but with an extended neck, which acts like a nozzle. They are designed to reinforce the area where the flange attaches to the piping system. Key characteristics include:

- Suitable for: A range of industrial applications.

- Common Industries:

- Oil and Gas Industry

- Petrochemical Plants

- Equipment like Columns and Heat Exchangers

Stainless Steel Flanges: Durability and Corrosion Resistance

Stainless steel flanges are essential components in piping systems where corrosion resistance and durability are critical. Advantages of stainless steel flanges include:

- High Corrosion Resistance

- Strength and Durability

- Resistance to Chemical Damage

Ideal for use in harsh environments like:

- Chemical Processing Plants

- Offshore Facilities

- Food and Beverage Industries

Welded Lugs: Applications in Valve Supports

Welded lugs are attachments welded onto pipes or equipment to facilitate lifting, supporting, or securing components within a piping system. Common uses include:

- Lifting: Provide attachment points for rigging hardware

- Supporting: Secure heavy components like valves

- Securing: Ensure stability and safety during operation and maintenance

Pipe Tees: Equal and Reducing Tees Explained

A pipe tee is a type of fitting used to split or combine fluid flow in a piping system. Tee pieces have three openings and are available in:

- Equal Tees: All openings are the same size

- Reducing Tees: One or more openings are a different size

They are crucial for:

- Branching pipelines

- Managing flow distribution efficiently

- Applications in plumbing, oil and gas pipelines, and chemical processing plants

Tailored Engineering Solutions for Diverse Industries

Our gallery represents just a small sample of the specialized components we've created for our clients. From large machined elbows to specialized nozzles and flanges, Balcombe Engineering has the expertise to design and manufacture components that meet the most demanding specifications.

Industries we serve include:

- Oil and Gas

- Chemical Processing

- Power Generation

- Water Treatment

- Mining and Minerals

- Aerospace

Whether you need a one-off specialized part or a large production run, our team is ready to bring your engineering challenges to life. Contact us today to discuss your specific requirements.

Ready to Start Your Specialized Project?

Our engineering team is standing by to assist you with your unique industrial component needs.

Contact Us