Flanges, Spectacle Blinds and Tubeplates / Tubesheets

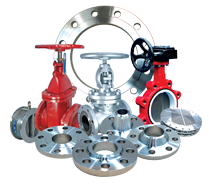

Balcombe Engineering Pty Ltd has been the leading Australian specialist manufacturer in the flange industry for over 50 years servicing a diverse range of customers for flange, spectacle blinds and tubeplates & tubesheets in the petrochemical, general industrial and food industries. The Melbourne facility is located in Hallam and houses Australia's largest range of flanges and valves as well as a comprehensive in-house manufacturing facility. Large stocks and in-house manufacturing enables Balcombe to provide any required flange, spectacle blind or valve in a few hours (if it is in stock) or between next day and 2 weeks delivery, if it has to be custom manufactured.

The company operates out of a purpose built complex of over 6000sqm. This Melbourne complex is located in Hallam, 1 minute from the intersection of the Princes Hwy and the South Gippsland Hwy, providing rapid access to the freeway system that cuts through Melbourne linking the major highways, the port and the airport. Such ease of access helps make freight carrier service fast and efficient. Our generous loading bays and forklift facilities make loading orders to be transported a fast, safe and painless task.

Experience & Service

Our experienced sales staff have mostly been in the flange industry for decades and are able to assist customers in unravelling the complex flange specifications ensuring you get the right advice every time. To enable real time information all sales staff use a comprehensive, fully integrated computer based Enterprise Resource Planning solution covering quotations, stock holdings orders, manufacturing and shipping. This system enables sales staff to immediately answer your stock availability and ex stock pricing queries then send you a formal quote. Additionally we can track the progress of your order and advise if the order is complete, packed and ready for shipment. So if it's a ASME/ANSI flange, DIN flange, AS2129 flange, AS4087 flange, pipeline flange, spectacle blind or tubeplate, you will get a rapid and accurate answer.

Flange Standards

Australia uses a variety of flange standards including ASME (American Society of Mechanical Engineers B16.5, B16.47) for oil and gas, Australian standards for general industry (AS2129) and water (AS4087) and British and European standards (BS4504 and EN1092) for imported pumps. To cater for these applications we are required to keep a comprehensive range of all these standards of flanges and valves. Typically we stock items to AS2129, AS4087, EN1092, ASME/ASNI B16-5, ASME/ASNI B16.47 flanges in sizes up to 1200 mm ID. Valves are stocked with AS2129 and ASME/ASNI B16.5 flanges. Applications vary widely and require flanges of different materials ranging from stocked materials such as standard carbon steels like GR250 and A105, low temperature carbon steel LF2, stainless steel 304, 316, 2205(SAF) to special order Chromoly and exotic alloys like Hastelloy and Incoloy.

Custom Fabrication and Expert Service

Balcombe Engineering excels in custom manufacturing, complementing our extensive stock of flanges and valves. Our state-of-the-art CNC facility, equipped with a 10-ton gantry crane, produces:

- Custom flanges up to 2 metres in diameter

- Specialist spectacle blinds for pipeline isolation

- Bleed rings

- Tubeplates for heat exchangers (up to 2 metres diameter)

- Self-reinforced long weld necks

Our experienced sales team, backed by an integrated Enterprise Resource Planning system, provides expert advice on complex flange specifications. We offer real-time information on stock availability, pricing, and order tracking.

Our product range includes:

- ASME/ANSI B16.5 compliant flanges

- DIN standard flanges

- Australian AS2129 standard flange

- AS4087 water industry flanges

- Custom pipeline flanges

- Spectacle blinds for pipeline maintenance

- Precision-engineered tubeplates

Quality Assured

Balcombe Engineering has a long history of supplying an extensive range of flanges and valves to specification and on time. To this end Balcombe Engineering maintains an ISO 9001:2015 quality assurance system audited by Lloyds and are active throughout the entire business from quoting right to packing and despatch. Our history is extensive with the company participating in projects like Goro Nickel, Woodside LNG train 5, Woodside LNG Pluto, Wheatstone Truenergy and the Sugarloaf pipeline.

Our huge range, extensive experience and ability to custom manufacture quickly to client requirements make Balcombe Engineering your first choice for flange and valve requirements.