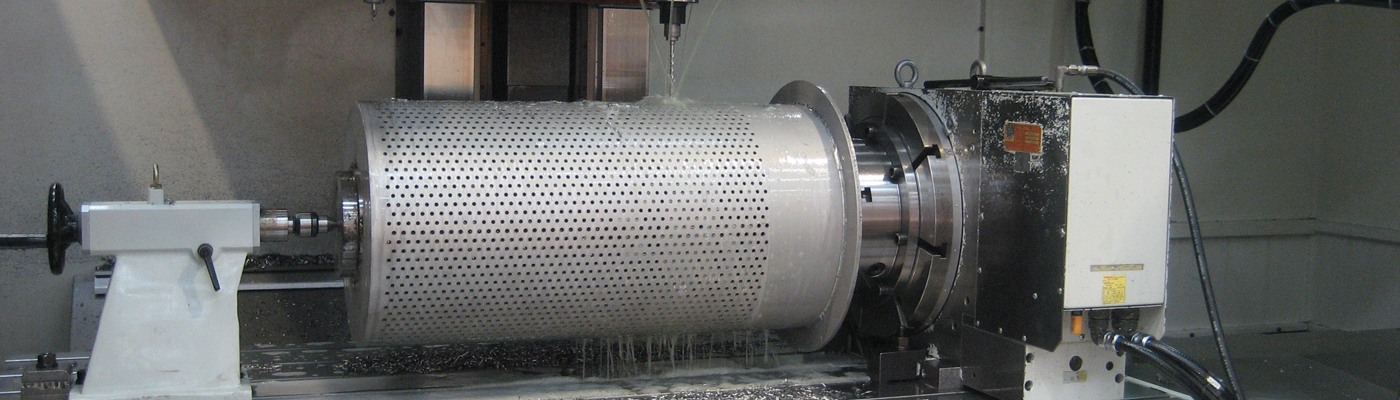

Our Manufacturing Capability

Balcombe Engineering have invested heavily in up-to-date CNC (Computer Numerically Controlled) machines to enable us to quickly machine flanges to custom requirements, while maintaining the finishes and tolerances demanded by the flange industry. Quality is paramount to all aspects of Balcombe's Hallam (Melbourne) manufacturing facility. The management system is accredited to ISO 9001:2015 and all aspects of the flange manufacturing process are controlled and monitored under this accreditation.

Facing a large fabrication

Components and flanges made locally are often paired with flanges or parts from the other side of the globe. Instrument calibration is the tool that guarantees that flanges from disparate sources fit everytime. A comprehensive instrument calibration system used at Balcombe tracks and maintains the accuracy of all measuring instruments. This includes items such as vernier callipers, micrometers, rulers and thread gauges.

Most importantly, we ensure that the staff that operate these machines and check conformance are fully trained and familiar with, not only the machines they work on and the instrumentation they use, but the range of flanges, boiler components and pressure devices we manufacture.

Capable machines, calibrated measuring equipment, competent experienced staff and a fully accredited ISO 9001:2015 management system are the key components to Balcombe's reputation as a premium specialist flange manufacturer.