Standards, Materials, Sizes and Variations - Great Delivery

-

Size Range: 15 mm-1500 mm (1/2"-60")

-

Ratings: 150 lb-2500 lb to suit ASME/ANSI B16.5 and ASME B16.45

-

Sealing Type:

Flat Face,

Raised Face,

Ring Joint

-

Sealing Finish:

Spiral Finish 3.2-6.3µm for facings

-

Ports:

Socket Weld,

Threaded,

Flanged

-

Materials: Orifice Flanges A105, LF2, 304/304L, 316/316L, UNS31803,

Orifice Plates A516 GR70, AS1548-PT460 A240 304L, 316L. Other materials are available on request.

-

Custom items: Our time frame for delivery is

usually 10-20 days.

-

Also called:

Metering Flanges,

Restriction Plates,

Bleed Rings,

Bleed Rings with holes,

Test Inserts,

Drip Rings,

Flushing Rings

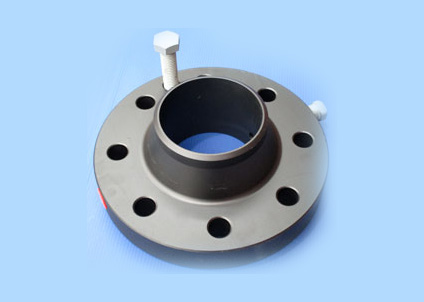

An Orifice flange is designed to measure

flow. They sit either side of an orifice

plate which is a controlled restriction. The Orifice plate fits in the line between two flanges

and is bolted

in place. Fluid dynamics then enable the designer to monitor the flow by monitoring the pressure before and

after the orifice.

An Orifice flange assembly consists of two ported flanges, plugs, a

jacking bolt and, may or may not be

supplied with bolts.

Orifice Flange Stamping

Typically an Orifice flange will be stamped

showing its size, rating, standard, material, heat number,

Balcombe Engineering stamp and production traceability code. Balcombe Engineering can arrange for your

own part identification and process traceability to be stamped on the Orifice flange.

Orifice Plates

The Orifice flange surrounds an Orifice plate. This Orifice plate provides a known aperture that can be used

with other process factors to calculate flow information.

Orifice Plates Stamping

Typically an Orifice plate will have stamped

showing its size, rating, standard, material, heat number,

Balcombe Engineering stamp and production traceability code. Balcombe Engineering can arrange for your

own part identification and process traceability to be stamped on the Orifice plate.

Orifice Flange Standards

Balcombe Engineering manufactures and stocks Orifice flanges in

Australia for a variety of industries. The

most commonly used standard is ASME B16.36 which covers Orifice flanges

for pipes up to nominal bore of 600mm

depending on the pressure class. This standard refers repeatedly to B16.5 and uses the B16.5 hole and

sealing

face diameter. Mostly, B16.5 Weld Necks cannot be converted to Orifice flanges.

Other standards exist and Balcombe Engineering are able to rapidly manufacture Orifice flanges to comply

with

these standards or company specific drawings.

Orifice Flange/Plate Sealing Finishes

Typically Orifice flanges and plates are produced as a flat face, raised face or ring joint sealing surface

depending on the application requirement. The finishes are identical to those under ASME/ANSI B16.5. The spiral

sealing face is a specified finish typically Ra 3.2µm-6.3µm.

Orifice Flange Material

As an Australian manufacturer, Balcombe Engineering is able to manufacture Orifice flanges in a material with

the testing as required by the client specification. Typically Orifice flanges will be manufactured from

carbon or stainless steels. Typical carbon steel materials are forgings like A105, A350 LF2, A350 LF3. In

corrosion resistant materials A182 F316L, F304L, UNS31803 are common. Less common but easily supplied are

Duplex F51 and Incoloy 625.

Additionally, specialist finishes are available such as galvanising, PTFE coatings and linings and various

epoxy finishes.

Corrosion Protection and Packaging

An Orifice flange will always have 2 sealing faces and two weld

preparations, which require significant face

protection.

Whether you want the Orifice flanges protected for 2 weeks or 2 years, Balcombe Engineering has a packing

system that ensures that Orifice flanges arrive at the installation in good condition. Our sales team is

happy to provide additional information if more robust corrosion protection is required.

Special Orifice Flanges

Sometimes a specific engineering requirement may dictate the need for special material and construction to

produce the Orifice flanges. Typical changes are the number and type of

ports. The ports may be screwed,

socket welded or have flanged extensions welded to them.

Balcombe Engineering is a manufacturer with full ISO 9001:2015 certification and

are able to produce to your

requirements including detailed testing and documentation. All material is traced through the system and

ITPs

and MDRs are available on request. Your order can be packaged in line with your engineering or project

specification and we are set up to complete the tasks within remarkably short delivery time

frames.